Important and uses of DC motor in our life

DC Motor is all around us. In our homes alone, nearly all mechanical and electrical movement you see around is brought about by a DC (direct current) electric motor and AC (alternating current) electric motor. Zénobe Gramme invention, the Gramme device, was the first electric motor that pulled off in the field.

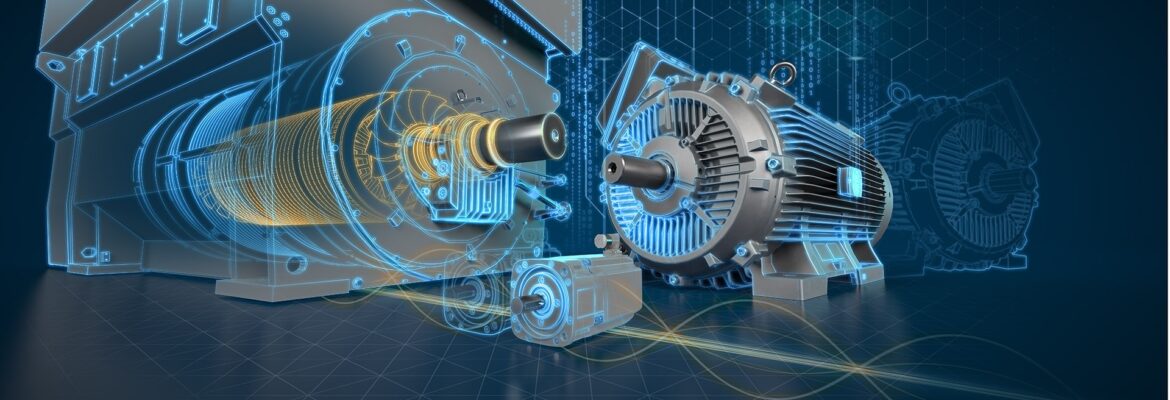

In general, a simple DC electric motor consists of six basic parts. These are the rotor or armature, brushes, axle, commutator, field magnet, and DC power supply. Those who previously played with magnets are familiar with the elementary principle of magnets, that similar poles repel and opposites attract. The repelling and attracting electromagnetic forces inside an electric motor make the DC motor to create rotating motion. Magnets are polarize, with a negative and a positive section.

The Complete Guide to DC Motors:

A DC electric motor needs at least one electromagnet. The electromagnet is typically to found in the motor’s hub and rotates in the permanent magnets. The coil is place in a fix magnet. The electric flow in the coil is deliver by means of two brushes that produce moving connections with a split ring. In this case, the DC motor’s wheel is the electromagnet. The two permanent outer magnets are the negative and the positive. Now, suppose that the right magnet is positive and the left magnet is negative.

The coils of wire on the wheel of the DC motor are being brought in with electric flow and this current ignites a magnetic drive. And, since opposite charges attract and similar charges repel, the wheel shifts in order for its negative piece turns over around to the right and the positive section of the wheel moves to the left. The magnetic force enables the wheel to spin thus, the movement is utilize to perform and operate. DC motors are largely employ for multiple applications such as remote control cars and electric razors.

Power Output/Horsepower: The designer will need to know what the rated speed and torque parameter that your system requires.

Environmental Conditions: It is always important to advise the motor designer what environments the motor will see.

As you can see there are many different types of motors to choose from. There are also many factors use in the choice. By working with a design engineer you can ensure to get the right motor for your application. This is why it is important to seek out a manufacturer before finalizing any systems design. Since its inception, The Standard motor range has been copy by many companies over the years and is one of the most popular of all small geared AC and DC Motors available today. It is use in a multitude of products such as packaging machines, conveyor systems, automated shelving systems. Pizza ovens, robotics and has more uses today than ever conceived by the original designers! The range of Standard Motors are available in AC Single Phase, Three phase and DC with the major models being Induction, Reversible, Electromagnetic Brake and Speed Controlled motors.